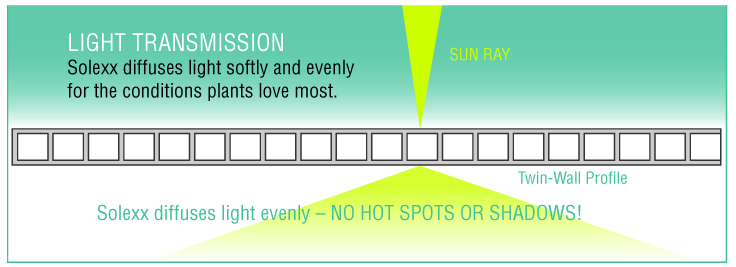

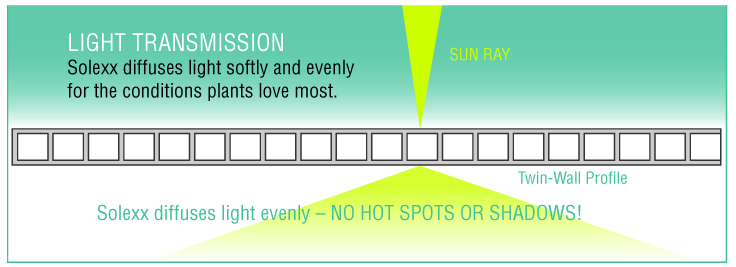

Capturing the Benefits of Diffuse Light

Solexx covering is designed to diffuse light evenly. Light bends and reaches into every corner to touch all foliage, not just the upper canopy. Such consistent growing conditions allow plants to develop uniformly for an even crop ready for market simultaneously and up to 25 percent faster.

Solexx light is best for your business:

- Eliminates directional light that results in hot spots and shadows

- Lowers labor costs that are associated with rotating plants (plants mature at the same time)

- Accelerate plant growth by up to 25 percent

- Minimize extreme temperature fluctuations - temperature changes gradually

- Keeps the greenhouse from overheating and plants from burning

- Reduce the risk of employee injuries from falls that occur while whitewashing the greenhouse

Designed for Efficiency and Longevity

Solexx provides superior insulation, holding in warmth to keep heating costs low. Solexx has one of the highest R factors of 2.3R on the market, indicating it holds heat better than the competition and provides hundreds or thousands of dollars in energy savings. Solexx withstands the harshest elements – including snow, wind and hail – without fading, yellowing or cracking over time. Coverings have a 10-year limited UV warranty, but an even longer life expectancy. Best of all, maintenance is simple, and panels are readily available and easy to replace if needed.

Solexx Retains Heat 65% Better Than Poly Film

Compare the insulation quality of Solexx to other greenhouse coverings on the market.

| 5mm Solexx Panels* |

2.30 |

0.43 |

| 3.5mm Solexx Panels* |

2.10 |

0.48 |

| 8mm Triple-Wall Polycarbonate |

2.00 |

0.50 |

| Double Pane Storm Windows |

2.00 |

0.50 |

| 10mm Twin-Wall Polycarbonate |

1.89 |

0.53 |

| Double Polyethylene Film 6 mil** |

1.70 |

0.60 |

| 8mm Twin-Wall Polycarbonate |

1.60 |

0.63 |

| 6mm Twin-Wall Polycarbonate |

1.54 |

0.65 |

| Double Polyethylene Film 6 mil** |

1.50 |

0.70 |

| 4mm Twin-Wall Polycarbonate |

1.43 |

0.70 |

| Single Pane Glass, 3mm |

0.95 |

1.05 |

| Corrugated Polycarbonate |

0.88 |

1.14 |

| Poly Film 6 mil |

0.83 |

1.20 |

| Corrugated Fiberglass |

0.64 |

1.56 |

- R-Value - The measurement of insulating ability of the material. The higher the R-Value number the greater the insulation value.

- U-Value - The measurement of heat loss through the material. The lower the U-Value the less heat is escaping.

*Independent testing, Solexx with caulked flutes.

** Requires constant inflation to maintain R-Value.

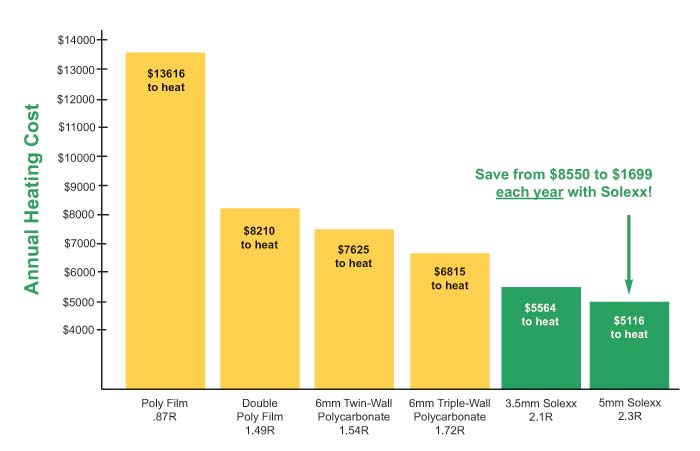

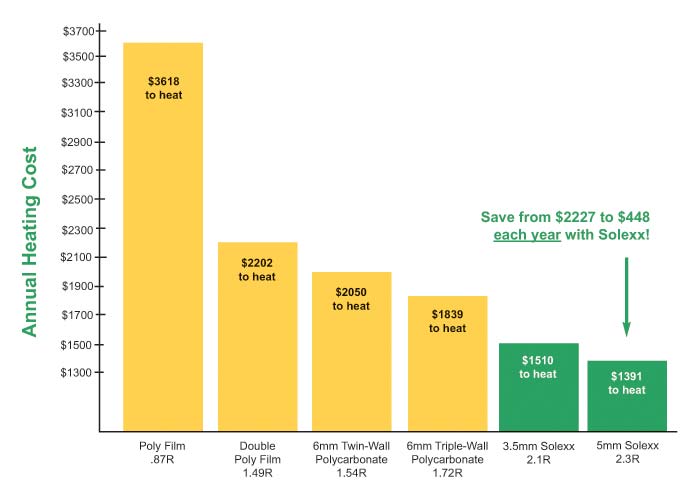

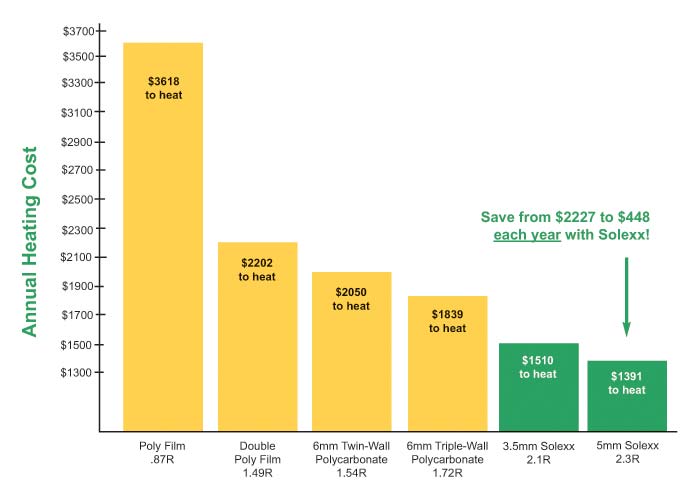

Energy Saving Analysis

Below are comparisons of annual heating costs with different greenhouse covering options. A significant amount of money is saved by using Solexx plastic. With rising gas prices and a trend toward weather extremes, the savings are substantially greater than shown below. To receive an energy comparison based on your specific structure, submit your information on our quote form or you can follow the link to the USDA Virtual Grower to calculate it yourself.

Both examples assume:

| Structure Size: |

30′ x 100′ greenhouse |

| Temperature: |

Greenhouse kept at a minimum temperature of 45°F year-round |

| Heating Fuel: |

Propane, $2 per gallon |

| Data Resource: |

Compiled from the USDA Virtual Grower software |

EXAMPLE 1: Salem, Oregon – Somewhat mild climate, temperatures generally above 30°F

EXAMPLE 2: Fort Collins, Colorado – Fairly cold conditions in winter

EXAMPLE 2: Fort Collins, Colorado – Fairly cold conditions in winter

EXAMPLE 2: Fort Collins, Colorado – Fairly cold conditions in winter

EXAMPLE 2: Fort Collins, Colorado – Fairly cold conditions in winter